11-10/2025

NewsMore >

-

-

10-22/2025

-

10-20/2025

-

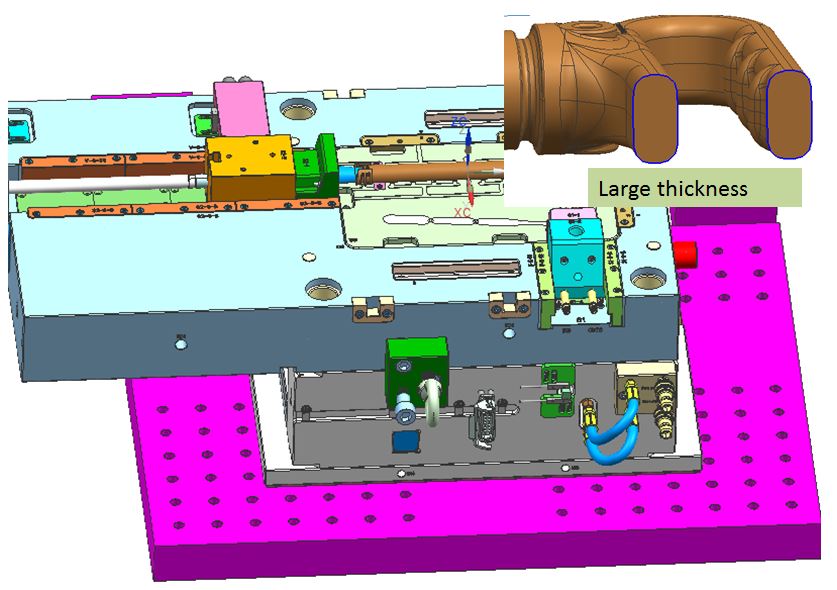

10-10/2025Our PA6+30%GF pipe quick connector is engineered as a high-strength junction in water-transmission systems. Manufactured via precision injection molding, it delivers leak-proof performance under elevated pressures. Complementary plastic holders offer lightweight, cost-effective support and display solutions for fittings and valves.

-

09-12/2025Discover protective travel box covers and Derco Mould’s custom injection-molding solutions for large plastic containers, engine covers, electrical enclosures, and OEM electronic components.

-

08-05/2025The automotive sealing systems industry is a critical part of the automotive supply chain, providing various sealing solutions for different types of vehicles such as passenger cars, commercial vehicles, and off-road vehicles. Sealing systems are used in various applications such as doors, windows, hoods, trunks, and engine compartments. The automotive sealing systems industry is a highly competitive and technologically advanced sector, with manufacturers constantly developing new and innovative sealing solutions that offer improved performance, durability, and sustainability. The industry is also increasingly focused on reducing the weight and cost of sealing solutions, while maintaining or improving their functional performance. Overall, the automotive sealing systems industry plays a vital role in the automotive industry, ensuring the safety, comfort, and performance of vehicles.

-

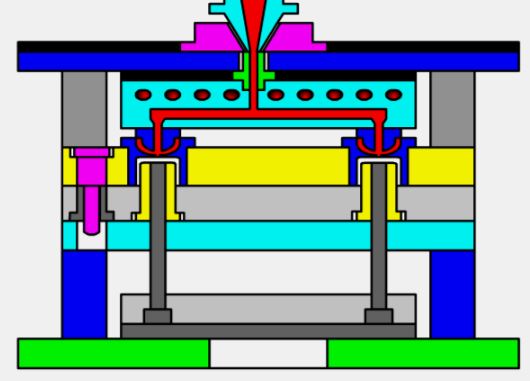

08-05/2025Stack mold is a type of mold used in injection molding to produce multiple parts per cycle. It is made up of two or more mold parting surfaces stacked one on top of the other, which allows for the creation of multiple cavities in each mold plate. The stack mold can produce two or more identical parts in a single shot, which increases production efficiency and reduces costs. There are a few challenges to using stack molds, such as increased complexity and maintenance requirements. Nevertheless, the benefits of stack molds make them a popular choice for high-volume production of plastic parts.

-

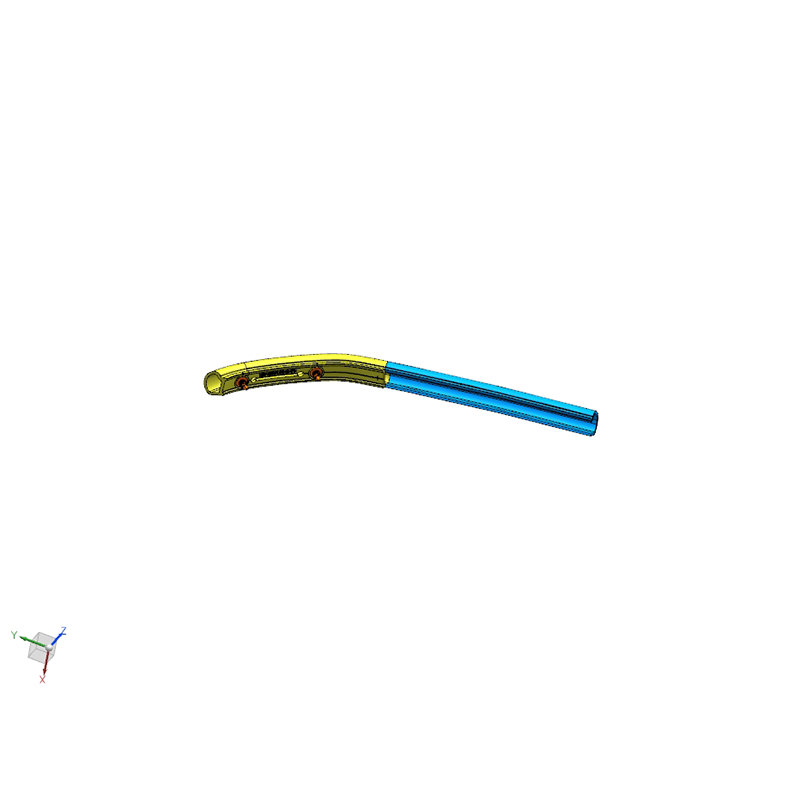

07-09/20252K mold as a two-shot mold or dual-material mold, is a type of injection mold that is used to manufacture complex plastic parts made of two different materials. The 2K mold process involves using two different materials and two different injection molding machines to produce a single part.

-

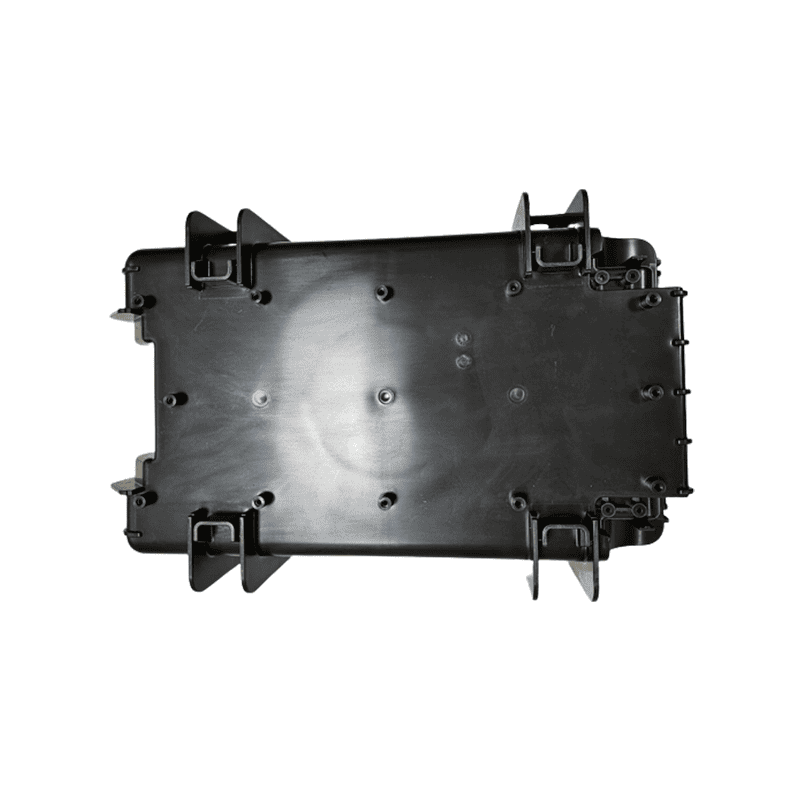

07-09/2025Automotive plastic molds are molds that are used to produce plastic parts for vehicles such as cars, trucks, and motorcycles. We are using advanced technology and materials to produce molds that are durable, precise, and efficient. The key features of high quality plastic molds include: 1. Precision: High quality plastic molds are designed with extreme precision to ensure that the final product is accurate and consistent. 2. Durability: High quality plastic molds are made of high-quality materials that are durable and long-lasting, even when subjected to heavy use. 3. Efficiency: High quality plastic molds are designed to optimize production efficiency, reducing cycle times and increasing productivity. 4. Customizability: High quality plastic molds can be customized to meet the specific needs of the customer, including size, shape, and material. 5. Ease of maintenance: High quality plastic molds are designed for easy maintenance and cleaning, reducing downtime and maintenance costs.

-

06-26/2025Electronic plastic mold r used for manufacturing various electronic plastic components such as computer parts, phone components, and other electronic devices. Making high quality electronic molds requires a combination of advanced technology, skilled craftsmanship, and attention to detail. Here are some steps to follow to make high quality electronic molds: 1. Design the mold: The first step is to design the mold using 3D and 2D software. The design should take into account the specific requirements of the electronic component that will be housed in the mold. 2. Select the materials: The material used to make the mold is critical to its quality. High-quality electronic molds are typically made of high-grade aluminum or steel. 3. CNC machining: Computer Numerical Control (CNC) machining is used to cut and shape the mold precisely according to the design specifications. 4. Surface finishing: The surface of the mold needs to be finished to ensure that it is smooth and free of any defects. This can be achieved through processes such as polishing or sandblasting. 5. Testing and validation: The mold needs to be tested and validated to ensure that it meets the required specifications and can produce quality electronic components. 6. Maintenance: Regular maintenance of the mold is essential to ensure that it remains in good condition and can continue to produce high-quality electronic components. By following these steps and using advanced technology and skilled craftsmanship, it is possible to produce high-quality electronic molds that meet the specific requirements of the electronic components they are designed to house.