Travel Box Cases: Protection & Style

Travel box cases shield suitcases and hard-shell luggage from scratches, dents, and dirt during transit. Available in materials ranging from woven fabrics and leather to rugged plastics, these covers come in multiple sizes and designs. Features may include:

• Reinforced corners and edge guards for impact resistance

• Exterior pockets or document sleeves for passports and tickets

• Elastic or zip-around closures for a snug fit

• Bright colors or patterns for quick identification on baggage carousels

Large Plastic Containers & Engine Covers

Beyond travel, injection-molded cases serve in industrial and automotive settings:

• Big Plastic Containers: Stackable, weather-proof bins for storage, transport, or waste management. Walls can be ribbed for extra strength, and lids custom-fitted to seal out moisture and dust.

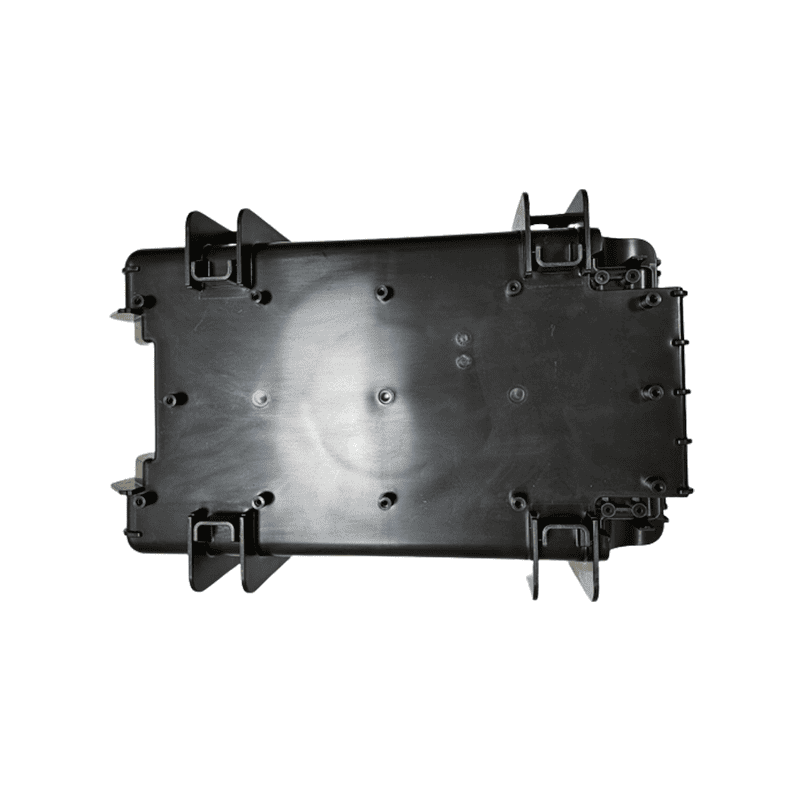

• Engine Covers: Precision-molded shrouds protect mechanical components from debris and heat. High-temperature thermoplastics or reinforced composites ensure dimensional stability under engine-bay conditions.

Electrical Enclosures & Electronic Component Housings

From consumer electronics to industrial control systems, custom-molded electrical cases and housings are critical for safety and performance:

• Junction Boxes & Control Panels: Snap-fit or gasketed designs to meet IP ratings against water and dust ingress.

• Connector & Relay Housings: High-insulation materials (PC, PA, POM) and tight tolerances for reliable electrical contact.

• Custom Inserts & Overmolds: Insert molding of metal terminals or overmolding of cables creates sealed, robust assemblies ideal for harsh environments.

Derco Mould’s Comprehensive Custom Injection Service

Derco Mould is a full-service injection mold specialist, offering end-to-end support:

• Initial Consultation & DFM Analysis: We start by understanding your application—load requirements, environmental factors, and regulatory standards—before selecting the optimal resin and gate layout.

• CAD/CAM-Driven Tool Design: Our engineers use the latest software to craft cavities for complex geometries, ensuring uniform wall thickness and proper draft angles.

• Precision Machining & Assembly: High-tolerance five-axis CNC machining and automated electrode manufacturing guarantee mold accuracy.

• Trial Runs & Validation: Trial molding verifies part dimensions, surface finish and mechanical performance; adjustments are made until all specifications are met.

• Volume Production & After-Sales Support: Once approved, your molds enter full-scale production. We provide maintenance, spare parts and on-site troubleshooting to maximize tool life.

Why Choose Derco Mould?

• Industry Experience: Decades of expertise in consumer, automotive, medical and electronics sectors

• Material Mastery: Guidance on selecting ABS, PP, PC, PA, POM and specialty blends for your project

• Fast Turnaround: Prototype molds in as little as 3–4 weeks; production tooling in 6–8 weeks

• Quality Assurance: ISO-compliant processes, in-house CMM inspections and batch traceability

Get Started Today

Whether you need a sleek travel box cover, a heavy-duty industrial container, or a precision-engineered electronic housing, Derco Mould delivers tailored injection-molding solutions that combine durability, functionality and aesthetic appeal.

Contact us to discuss your next project and learn how our mold-making expertise can bring your designs to life.