06-26/2025

The various components or products made from industrial plastic materials. These parts are used in different industries for various purposes such as in machinery, equipment, and consumer products. Some common industrial plastic parts include gears, bearings, valves, pumps, tanks, pipes, and fittings.

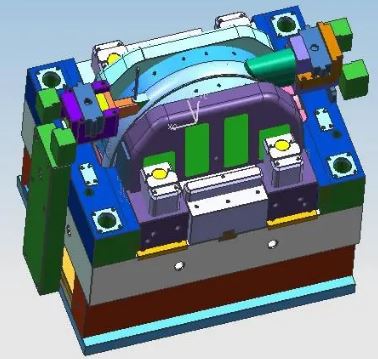

Creating good quality industrial plastic molds requires expertise in the design, material selection, and manufacturing process. Here are some important factors to consider:

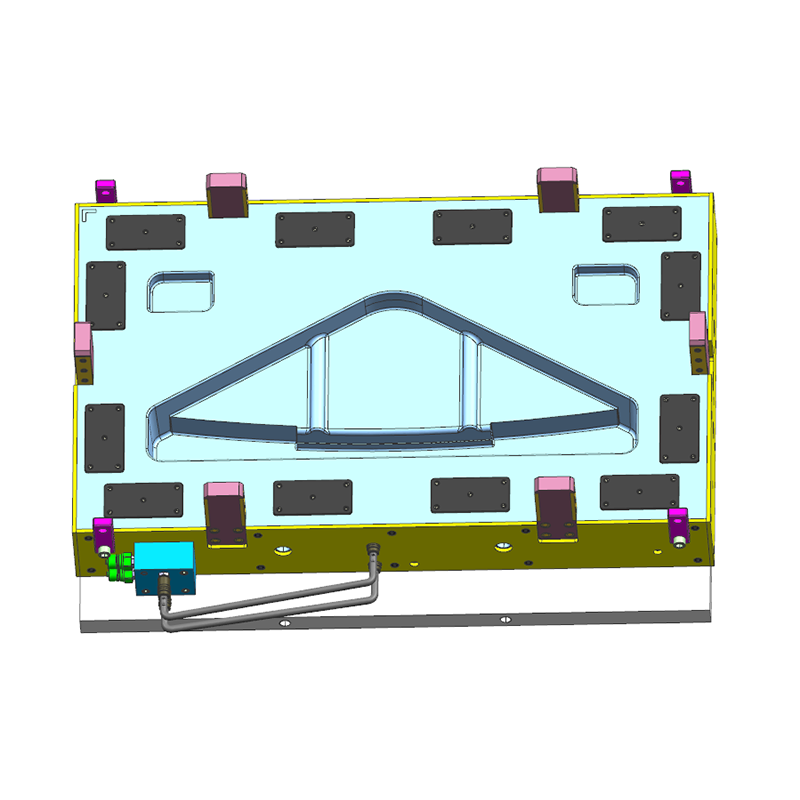

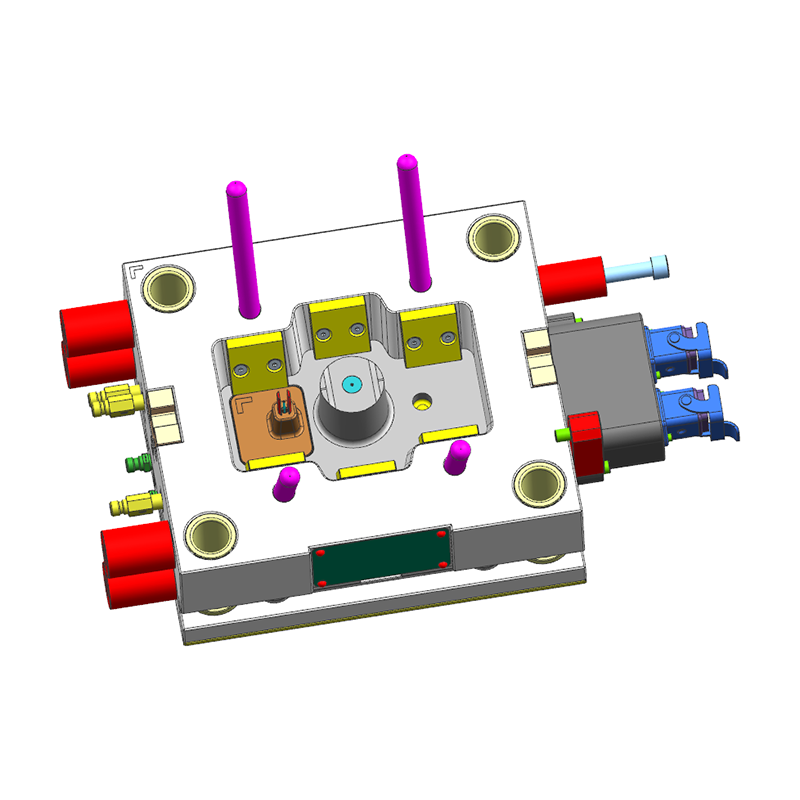

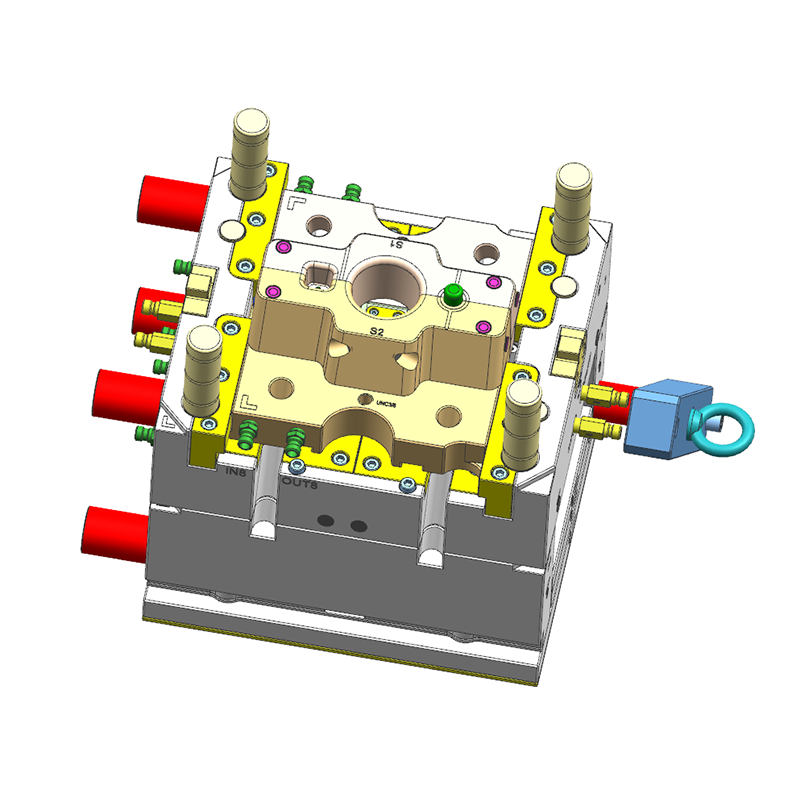

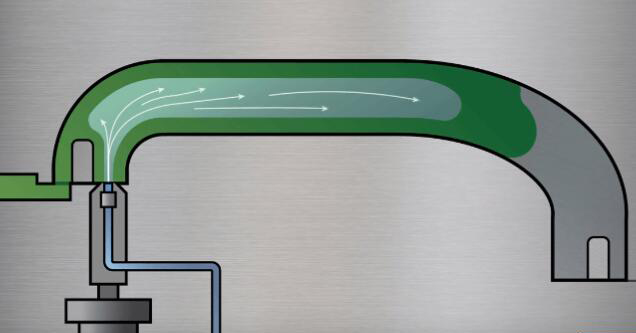

1. Design: The mold design should be optimized for the specific application and part geometry. A well-designed mold should consider factors such as mold flow, draft angles, and parting lines.

2. Material selection: The choice of material will depend on the specific application and production requirements. Factors to consider include temperature resistance, chemical resistance, and durability.

3. Manufacturing process: The manufacturing process should be optimized for the specific mold design and material. Common processes include injection molding, blow molding, and thermoforming.

4. Quality control: Quality control is essential to ensure the mold meets the required specifications. This includes inspection of the mold surface, dimensional accuracy, and material properties.

5. Maintenance: Regular maintenance is crucial to keep the mold in good condition and ensure consistent quality. This includes cleaning, lubrication, and periodic inspections.