06-26/2025

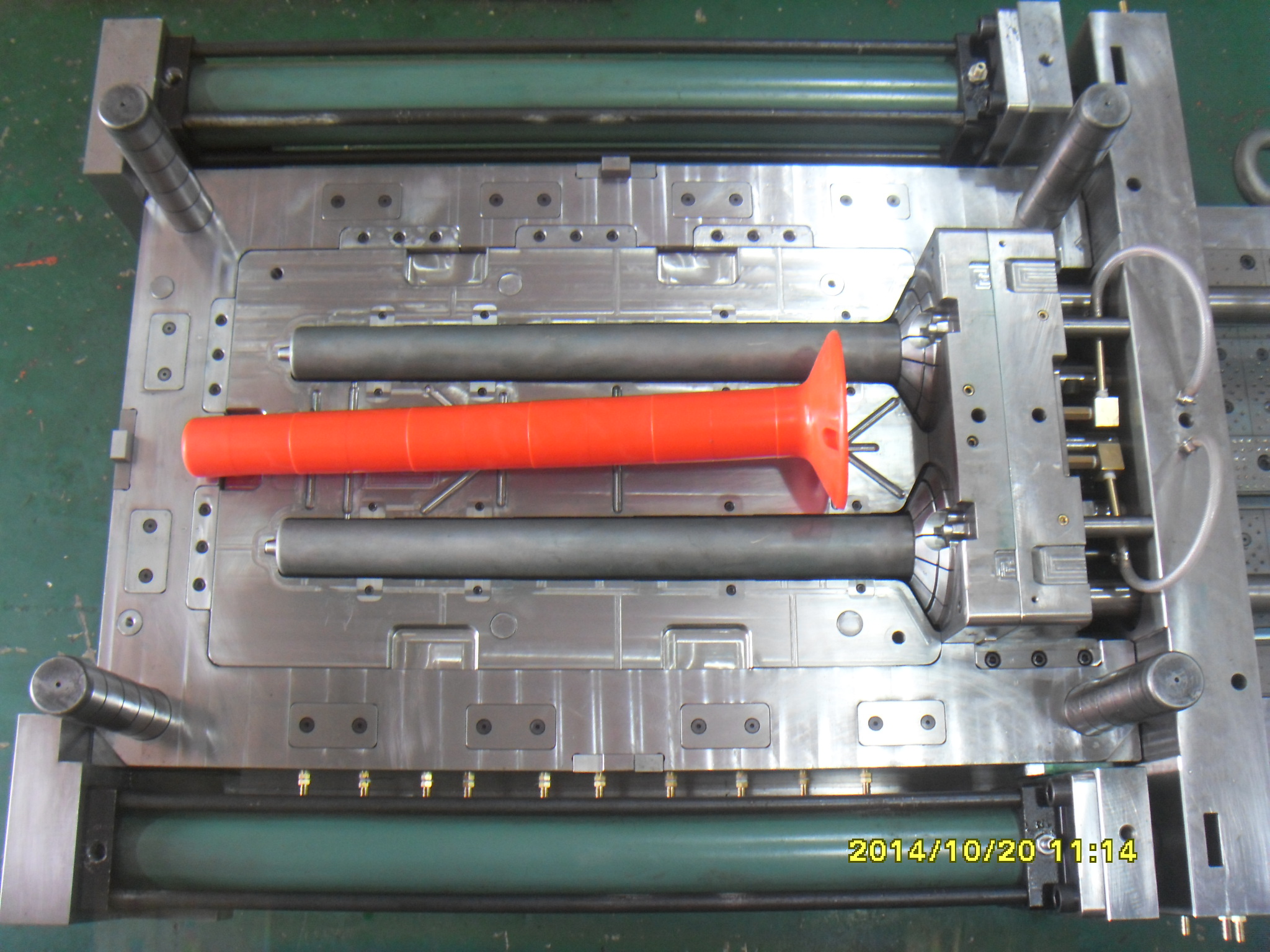

Electronic plastic mold r used for manufacturing various electronic plastic components such as computer parts, phone components, and other electronic devices.

Making high quality electronic molds requires a combination of advanced technology, skilled craftsmanship, and attention to detail. Here are some steps to follow to make high quality electronic molds:

1. Design the mold: The first step is to design the mold using 3D and 2D software. The design should take into account the specific requirements of the electronic component that will be housed in the mold.

2. Select the materials: The material used to make the mold is critical to its quality. High-quality electronic molds are typically made of high-grade aluminum or steel.

3. CNC machining: Computer Numerical Control (CNC) machining is used to cut and shape the mold precisely according to the design specifications.

4. Surface finishing: The surface of the mold needs to be finished to ensure that it is smooth and free of any defects. This can be achieved through processes such as polishing or sandblasting.

5. Testing and validation: The mold needs to be tested and validated to ensure that it meets the required specifications and can produce quality electronic components.

6. Maintenance: Regular maintenance of the mold is essential to ensure that it remains in good condition and can continue to produce high-quality electronic components.

By following these steps and using advanced technology and skilled craftsmanship, it is possible to produce high-quality electronic molds that meet the specific requirements of the electronic components they are designed to house.