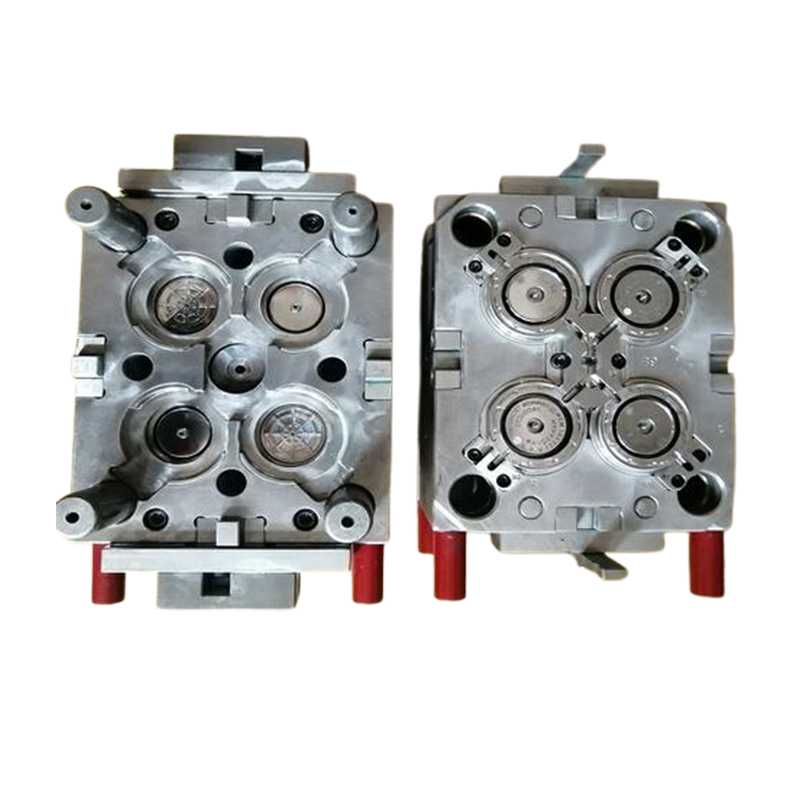

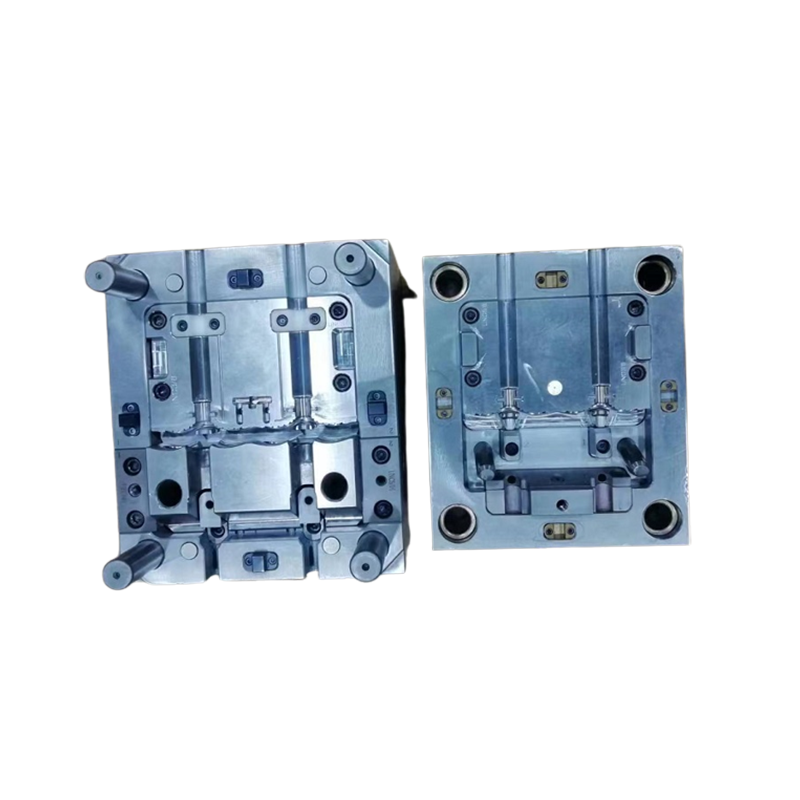

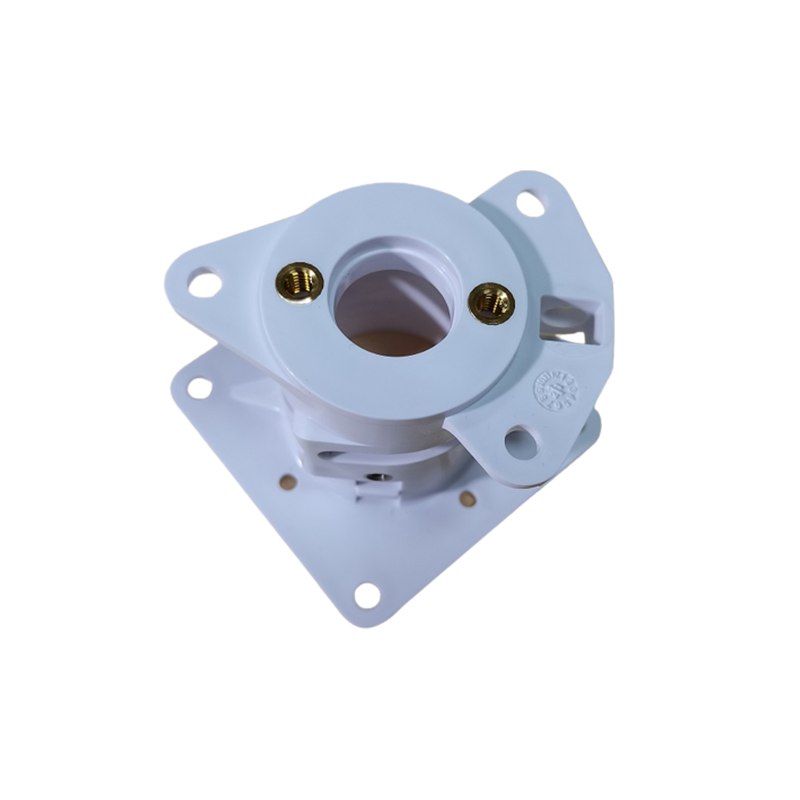

Medical Molds

Good quality medical plastic molds are designed and manufactured to meet the strict standards of the medical industry. These molds are used to produce parts and components for medical devices, equipment, and instruments.

Here are some key factors that contribute to the quality of medical plastic molds:

1. Material selection: Medical plastic molds require the use of medical-grade materials that are biocompatible and meet strict safety standards. These materials must be free of contaminants and impurities that could pose a risk to patient health.

2. Design: The mold design must be optimized for the specific application and part geometry. The design should take into account factors such as mold flow, draft angles, and parting lines.

3. Manufacturing process: The manufacturing process must follow strict protocols to ensure the molds are produced in a clean and controlled environment. Processes such as injection molding must be performed under cleanroom conditions to prevent contamination.

4. Quality control: Quality control is critical to ensure that the molds meet the required specifications. The molds must be inspected for surface finish, dimensional accuracy, and material properties.

5. Validation: Medical plastic molds must be validated to ensure they meet the required standards. This includes testing for biocompatibility, sterility, and other safety parameters.

Good quality medical plastic molds require expertise in design, manufacturing, quality control, and validation. It is essential to work with experienced professionals who have a deep understanding of the unique requirements of the medical industry to ensure the highest level of quality and safety.