08-05/2025

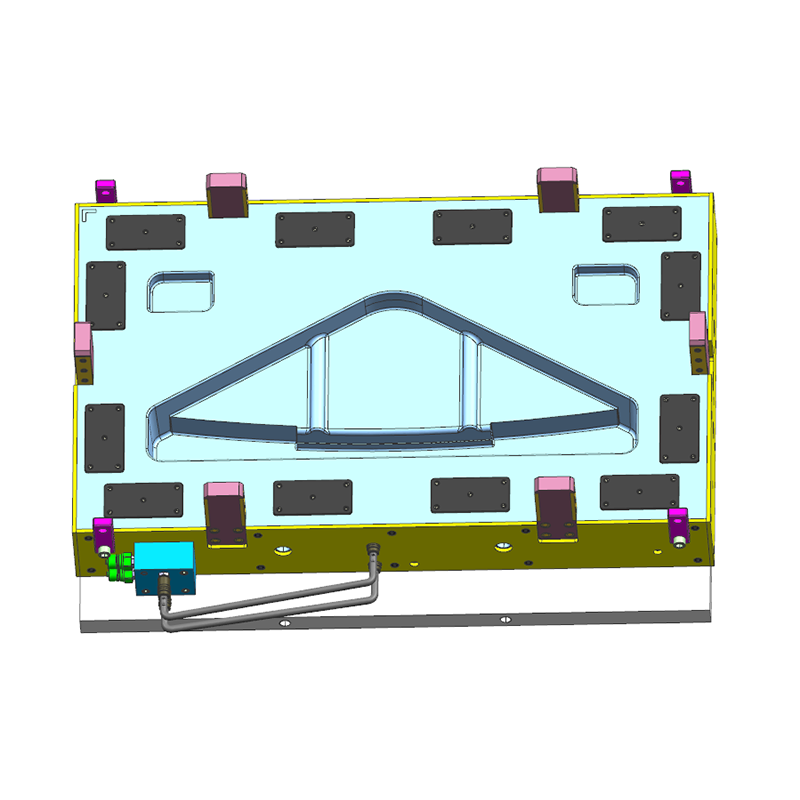

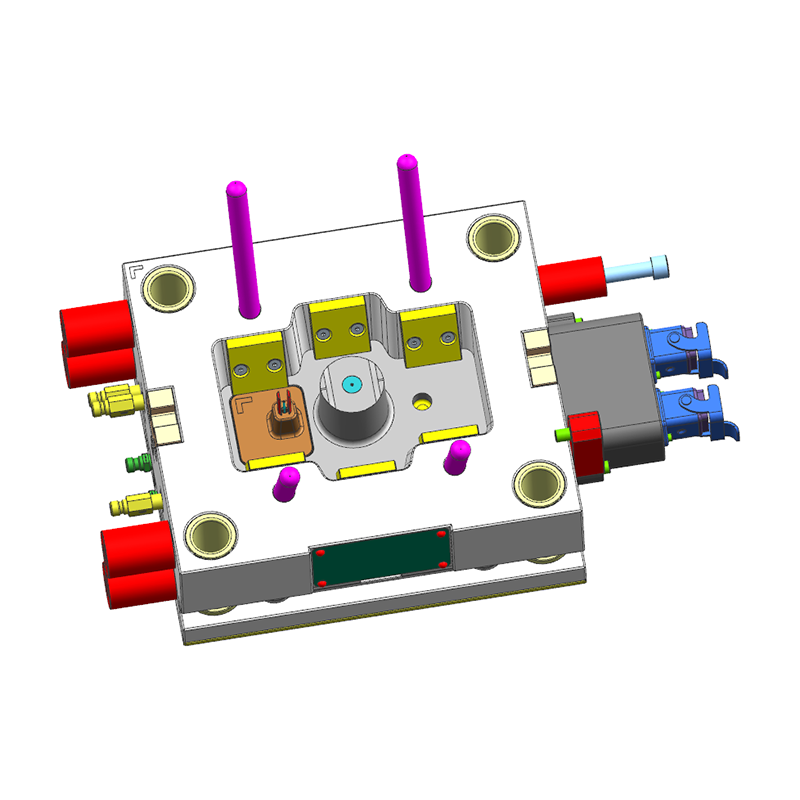

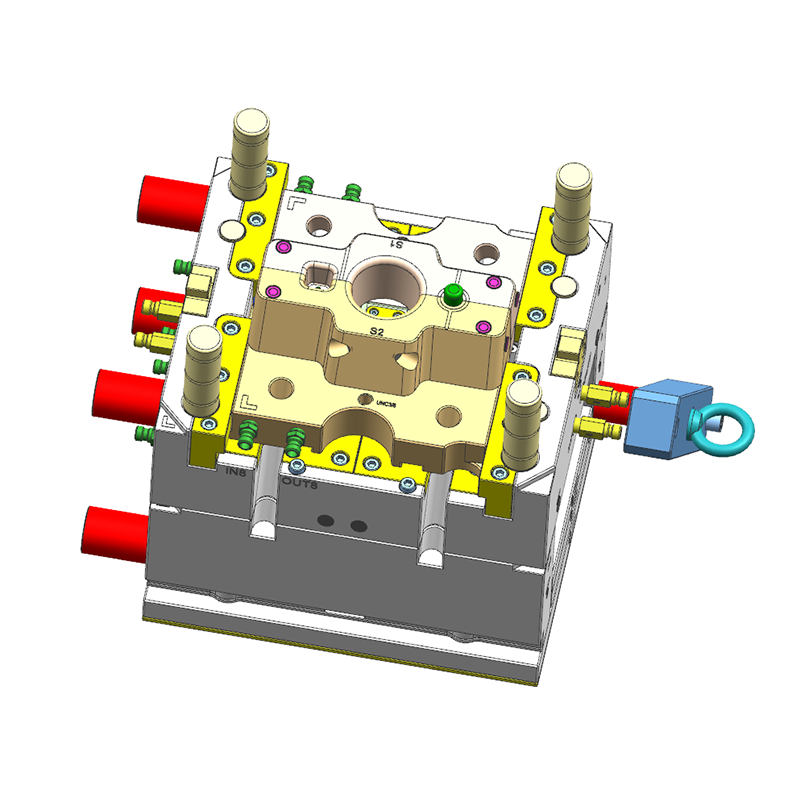

Stack mold is a type of mold used in injection molding to produce multiple parts per cycle. It is made up of two or more mold parting surfaces stacked one on top of the other, which allows for the creation of multiple cavities in each mold plate. The stack mold can produce two or more identical parts in a single shot, which increases production efficiency and reduces costs.

There are a few challenges to using stack molds, such as increased complexity and maintenance requirements. Nevertheless, the benefits of stack molds make them a popular choice for high-volume production of plastic parts.