Menu

- Home

- About Us

- Company Profile

- Certificate

- Service

- Injection Molding

- Mold Making

- R&D

- Management

- Project Management

- Work flow

- Quality Control

- Products

- Automotive Mould

- Exterior trim

- Vehicle part

- Automotive Panel Part

- Automotive molds

- Electrical Mould

- Electronica Plastic Parts

- Communication Box

- Electronica Mold

- Industrial Mould

- Bracket

- Pipe

- Industrial mold

- Medical Mould

- Medical Device

- Collection tube

- Medical mold

- Package Mould

- Cap

- package case

- Package mold

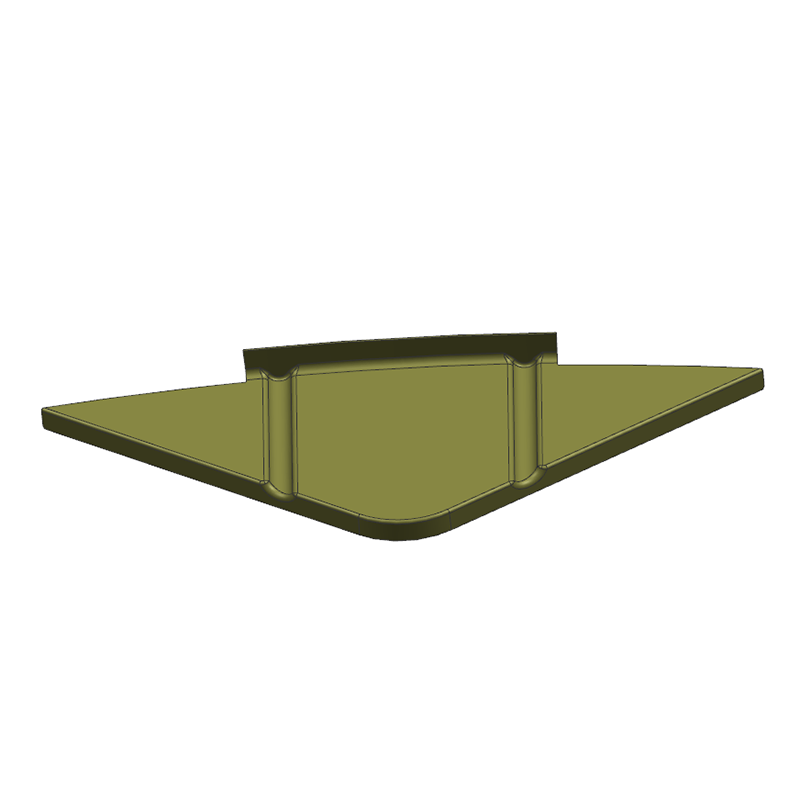

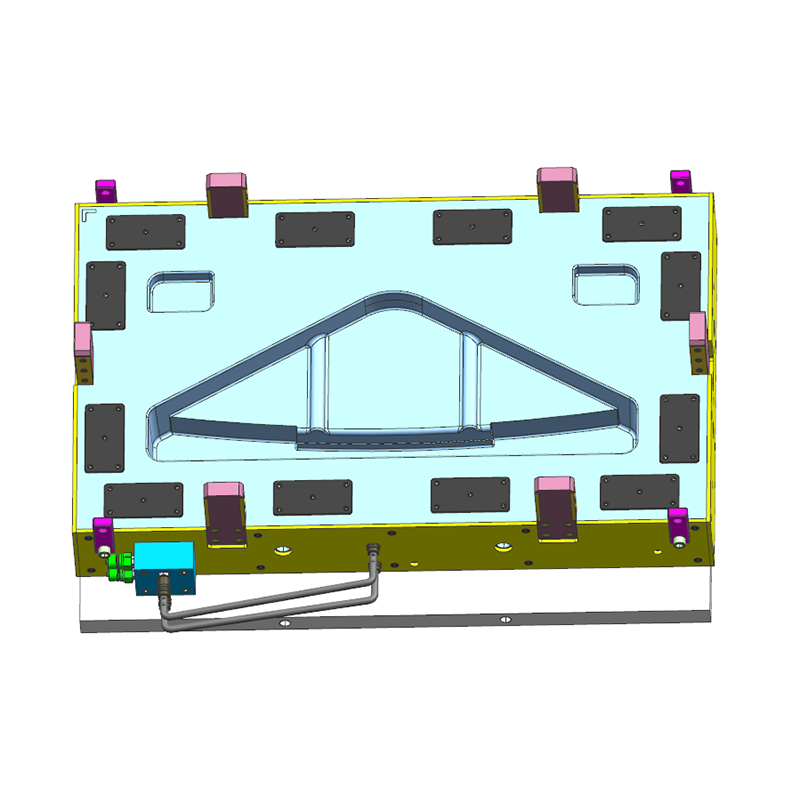

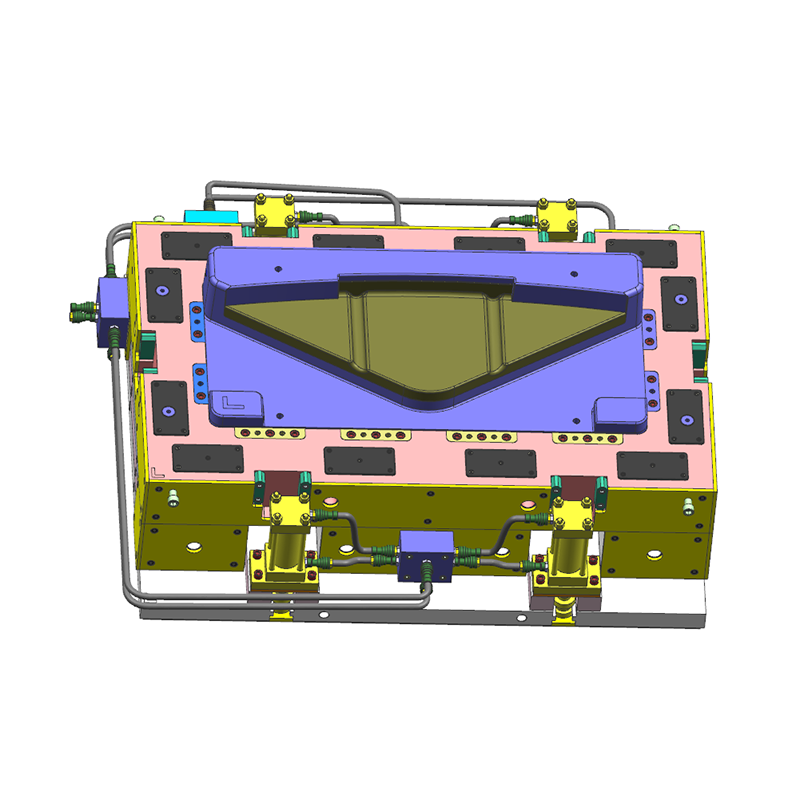

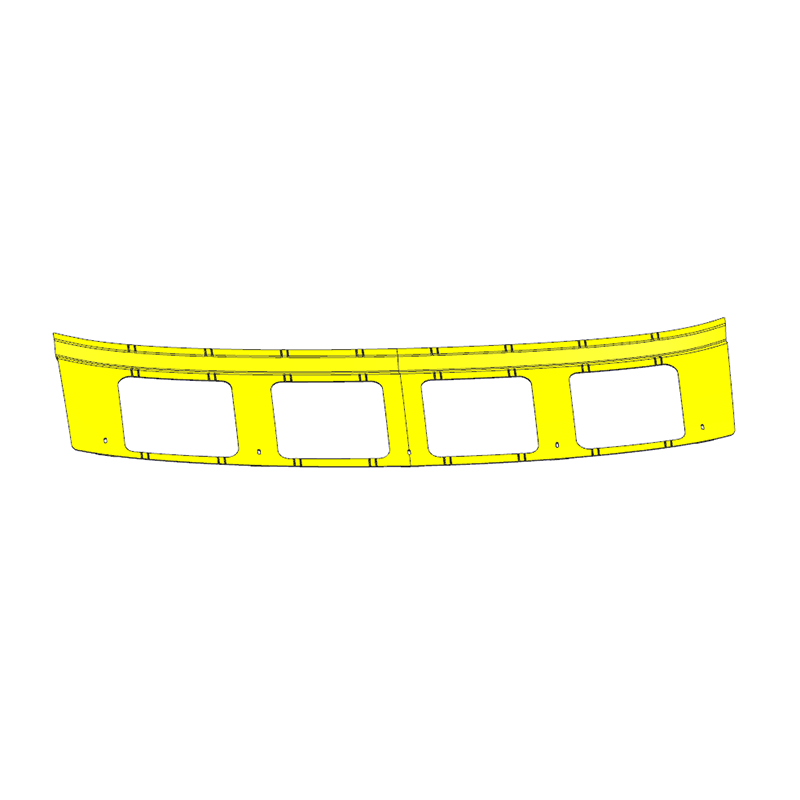

- SMC Mould

- Truck Products

- Rail transit

- SMC mold

- Rubber Mould

- Double injection

- Primary (door channel) seals

- Rubber mold

- News

- Corporate News

- Industry News

- Contact Us

Search

- Home

- >

- Products

- >

- Truck SMC parts

- >