Over-Molding: Advanced Multi-Material Manufacturing Solutions

Over-mold, or over-molding, is a manufacturing process that involves the injection molding of one material over another material to create a finished product with multiple layers. The process involves molding a base material, such as plastic or metal, and then molding a second material over the base material to form a final product with two or more layers.

Over-molding is a versatile manufacturing process that can be used to create products with multiple layers, colors, and properties. The process is widely used in various industries to create products that are durable, attractive, and functional.

Advanced Over-Molding Applications

At Derco Mold, we specialize in complex over-molding solutions that combine technical precision with innovative material science. Our capabilities include:

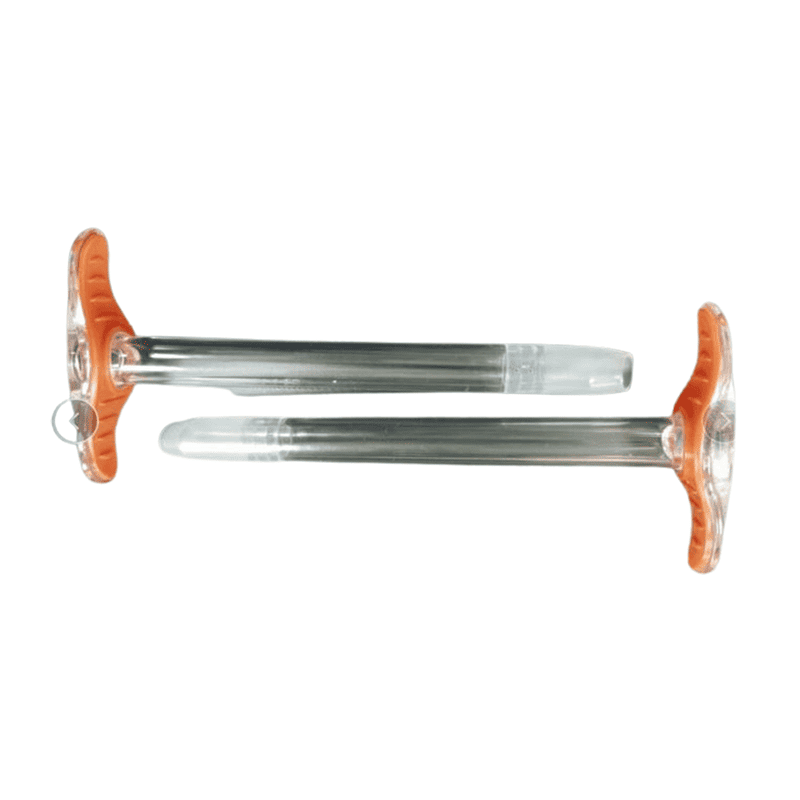

Medical Device Components: Creating soft-touch grips for surgical tools with antimicrobial TPE over-molds

Consumer Electronics: Producing waterproof seals and vibration-dampening layers for wearable devices

Automotive Parts: Manufacturing multi-density control knobs with rigid ABS cores and elastomeric overlays

Precision Engineering Expertise

Derco Mold maintains industry-leading tolerances of ±0.01mm for molds and ±0.02mm for molded parts. Our advanced capabilities include:

Multi-shot molding for complex geometries

Insert molding with metal and plastic combinations

Micro-over-molding for components under 5mm in size

Material Innovation

We've developed specialized material combinations for superior performance:

High-bond TPE/PP systems for permanent adhesion

Chemical-resistant over-molds for industrial applications

FDA-compliant material pairs for food contact

Quality Assurance Process

Every over-molded part undergoes rigorous testing:

Bond strength verification (ASTM D903)

Dimensional inspection with CMM

Environmental stress testing

Functional performance validation

Why Choose Derco Mold for Over-Molding?

25+ years of specialized over-molding experience

Complete in-house design and tooling capabilities

Rapid prototyping to production scaling

Global certification compliance (ISO 13485, IATF 16949)

Our team works closely with clients from initial design through full production, ensuring optimal material selection and manufacturability for every over-molded component. Contact us today to discuss your project requirements.