Innovations in Automotive Sealing Systems Drive Industry Advancements

The automotive sealing systems industry continues to evolve, with manufacturers developing cutting-edge solutions to meet the demands of modern vehicles. From endcap seals to advanced glass encapsulation seals, the sector is prioritizing lightweight, durable, and sustainable materials such as EPDM/TPV to enhance performance across doors, windows, hoods, and engine compartments.

Key Sealing Technologies Shaping the Market

Endcap Seals – Critical for preventing water and dust ingress in door and window assemblies, these seals now incorporate reinforced EPDM/TPV compounds for extended durability.

Glass Encapsulation Seals – As vehicle designs trend toward larger panoramic roofs and flush windows, precision 2K molds enable seamless bonding of glass to frames while reducing weight.

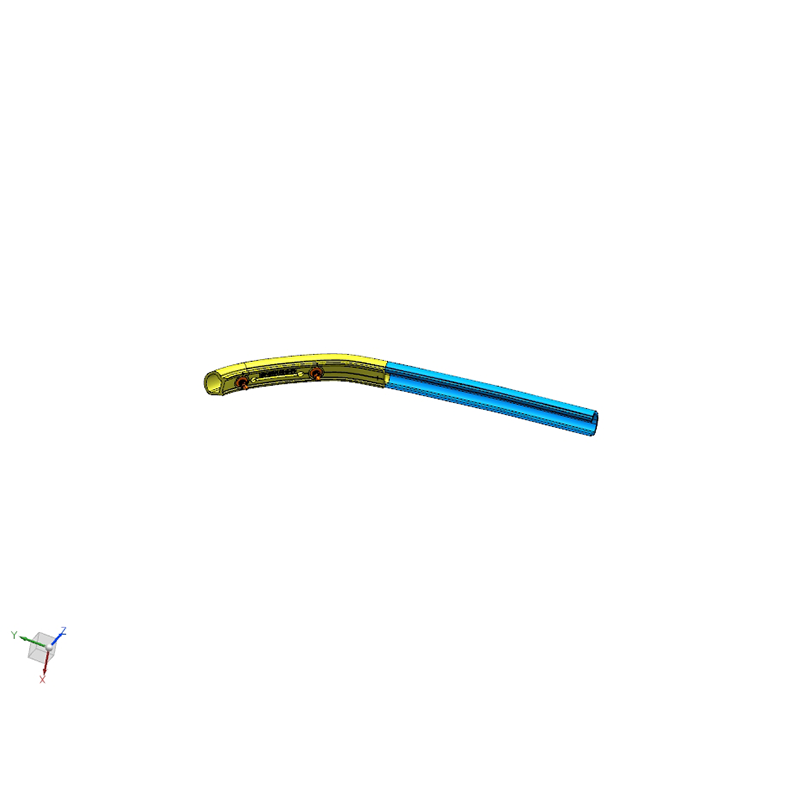

Over Molding Sealing – Combining multiple materials in a single process, over molding enhances structural integrity and reduces assembly steps for complex components.

Industry Challenges & Innovations

Weight Reduction – Manufacturers are optimizing EPDM/TPV formulations to maintain sealing performance while minimizing mass.

Sustainability – Recyclable rubber compounds and energy-efficient molding processes are gaining traction.

Cost Efficiency – Advanced 2K molds and automated production techniques help lower per-unit costs without sacrificing quality.

Derco: A Trusted Partner in Automotive Sealing Solutions

With over 15 years of expertise, Derco specializes in high-performance rubber injection molds for the automotive sealing industry. The company’s capabilities include:

✔ Custom 2K Molds – For multi-material sealing components

✔ Over Molding Solutions – Enhancing part durability and assembly efficiency

✔ EPDM/TPV Tooling – Optimized for superior weather resistance and longevity

"As vehicles become more advanced, sealing systems must evolve to meet stricter performance and efficiency standards," says a Derco spokesperson. "Our expertise in 2K molds and over molding sealing ensures automakers receive reliable, high-quality solutions."

Future Outlook

With electric vehicles (EVs) and autonomous driving pushing new sealing requirements, the industry is expected to see:

Increased demand for lightweight glass encapsulation seals

Growth in over molding applications for sensor housings

Expansion of sustainable EPDM/TPV material use

For automotive manufacturers seeking high-precision sealing molds, Derco offers end-to-end design and production support, ensuring optimal performance and cost efficiency.