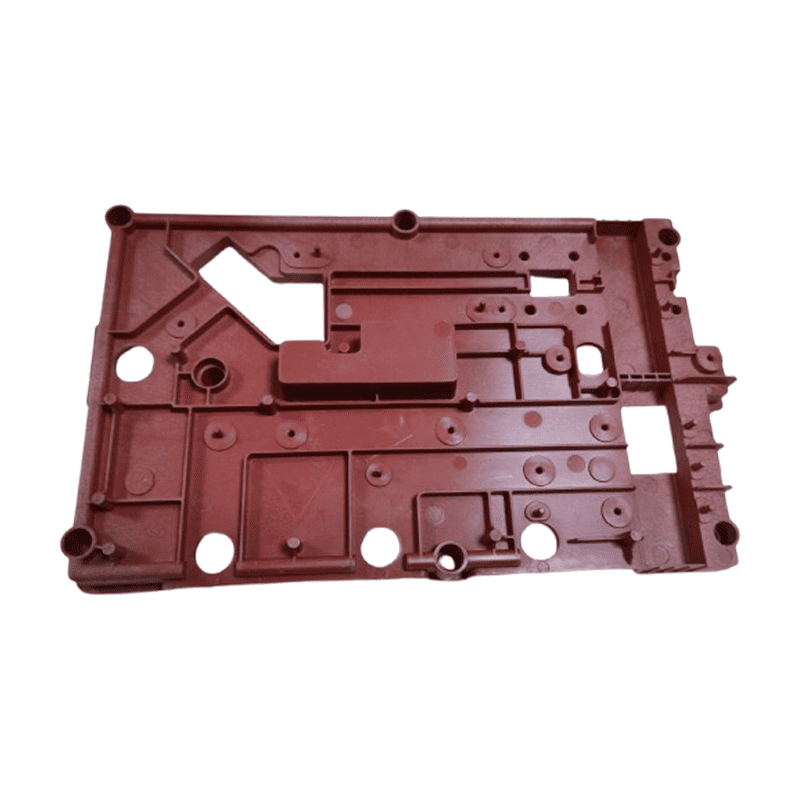

Advanced Industrial Plastic Mold Solutions for Precision Components

1. Comprehensive Mold Manufacturing Process

Our vertically integrated production system delivers exceptional quality molds for Plastic Brackets, Structural Shims, Pipes, and Covers:

Design Phase:

DFM analysis optimized for Plastic Bracket stress points

Wall thickness simulation for Pipe mold cavities

Ejection system engineering for complex Cover geometries

Precision Machining:

≤0.005mm tolerance on Structural Shim mold cores

Micro-milling (≤50μm) for medical Cover components

Multi-stage polishing (Ra 0.012μm) for optical-grade Plastic Brackets

Quality Validation:

3D scanning (≤5μm accuracy) for automotive Pipe molds

100% hardness testing on Structural Shim inserts

Production trials (minimum 10,000 cycles) for all Cover systems

2. Specialized Electrical Component Molding

For critical electrical applications, we offer:

Flame-Retardant Solutions:

30+ UL94 V-0/V-1 material formulations

Anti-tracking compounds for high-voltage Cover components

Halogen-free options for Plastic Bracket enclosures

Precision Features:

Micro-pins (≤0.2mm) for connector Structural Shims

Overmolding capabilities for composite Pipe fittings

LSR (Liquid Silicone Rubber) options for sealed Covers

Case Study: Our converter socket mold achieves:

0.02% flash occurrence rate

15-second cycle time

500,000+ shot lifespan

3. Material Science Expertise

Selecting the optimal material ensures longevity:

| Application | Recommended Material | Key Properties |

|---|---|---|

| Automotive Plastic Brackets | 30% GF-PA66 | High stiffness, heat resistance |

| Aerospace Structural Shims | PEEK | Extreme temp stability |

| Industrial Pipes | PVDF | Chemical resistance |

| Medical Covers | PC-ISO | Sterilization durability |

Advanced surface treatments:

TiCN coating for abrasive Pipe materials

Electropolishing for medical Cover molds

Plasma nitriding for high-wear Plastic Brackets

4. Industry-Specific Engineering

Automotive:

Underhood Structural Shim molds (withstand 150°C)

Interior Cover systems (Class A surface finish)

Fluid handling Pipe components (leak-proof gates)

Medical:

ISO Class 8 cleanroom Cover molding

Microfluidic Pipe networks (≤100μm channels)

Snap-fit Plastic Bracket assemblies

Industrial:

Large-scale Pipe production (≤3m length)

Wear-resistant Structural Shim components

UV-stable outdoor Cover systems

5. Technical Support Services

Our full-service approach includes:

Design Optimization:

DFM reports for Plastic Bracket projects

Moldflow analysis for complex Pipe geometries

Cooling simulation for Cover production efficiency

Production Support:

In-house mold trials for Structural Shim validation

Process parameter optimization

Operator training programs

Maintenance Programs:

Preventive maintenance schedules

Surface refurbishment for Plastic Bracket molds

Insert replacement services

6. Why Partner With Us?

15+ years specializing in Pipe, Cover, and Plastic Bracket molds

ISO 9001:2015 certified quality system

24/7 engineering support

98% on-time delivery record

5-year extended warranty available