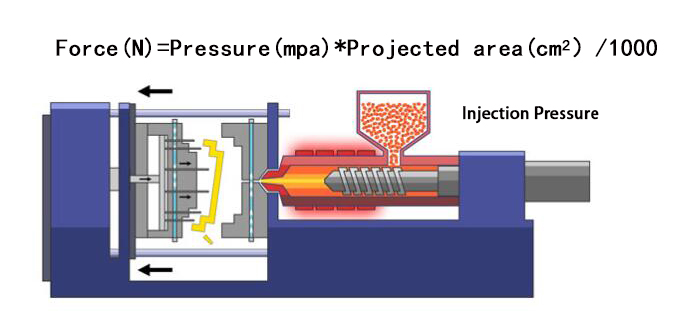

Clamping force of injection molding refers to the maximum force exerted by the clamping unit of the molding machine on the mold. When the molten material is injected into the mold through high speed and pressure, and outward force will be produced. The clamping unit of the molding machine must provide enough force to ensure that the mold is always kept tightly closed during production. So, how to calculate the clamping force? We will introduce some methods of clamping force calculation. The clamping forces received from the calculation are for reference only, and the actual figure depends on the molding machine you are using.

Clamping force calculation formula:

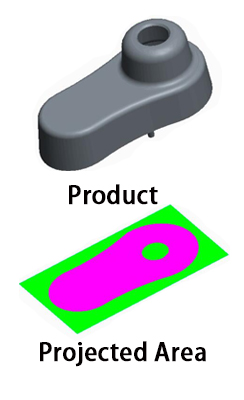

1. F=p*A/1000

P(kgf/cm²): cavity pressure in injection mold

A(cm²): total projected area

The cavity pressure in the injection mold is usually between 300-500 tons, and the total projected area represents the projection of the cavity and the rubber on the parting surface. Therefore, the clamping force mainly depends on the number of the mold cavity and the gate design of the mold structure.

2. F=KpS

Kp(t/cm²): Clamping force constant of material

S(cm²): projected area of plastic products.

This way of calculating the clamping force requires reference to the constant of the plastic material.

3. Precise calculation of clamping force

The precise calculation of the clamping force can be achieved through the mold flow analysis in conjunction with formula 1). The cavity pressure is mainly affected by 2). The number and position of the gate; 3). The size of the gate; 4). The wall thickness of the product; 5). The injection speed; 6). The viscosity of raw materials, etc.